🚚 Free Standard Shipping on All Orders

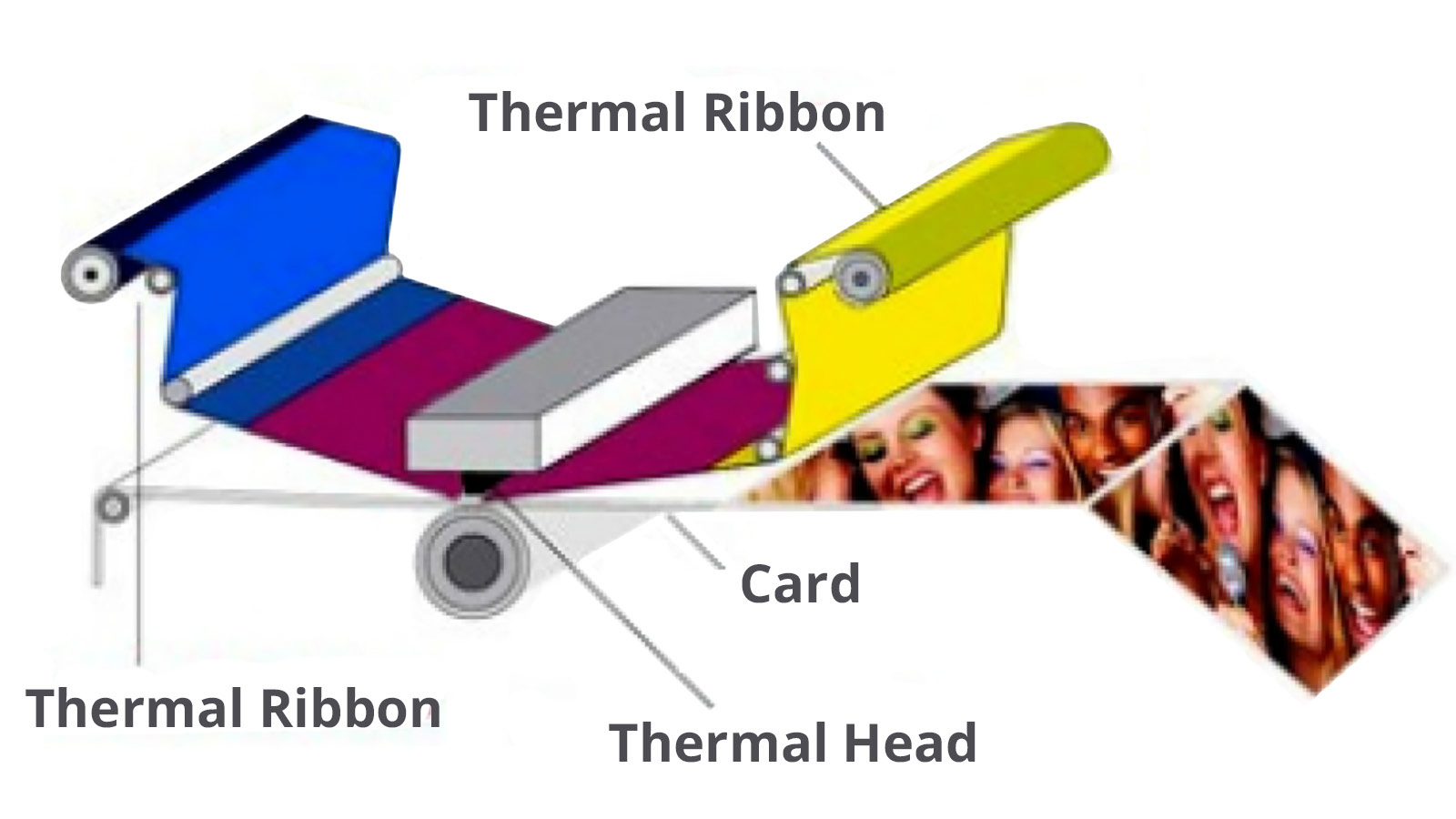

In order to select a printer that is compatible with your ID card design, there are several aspects of presentation to understand. The first of those and perhaps the most obvious is print quality. DPI or dots-per-inch refers to how detailed a printhead can produce images on a card. Current industry standards are 300-600 DPI, and the higher the DPI, the more vivid and detailed the image will be. In addition, print quality will be affected by the print technology utilized to print your cards. There are two technologies when it comes to printing ID cards. The first is Direct-to-Card (DTC), also known as dye-sublimation, which uses a thermal print process to transfer the image to a dye ribbon which in turn applies it to the card’s surface one color at a time. While this method is affordable and durable, it cannot produce an image that is printed edge to edge, so there will always be a white edge around the outside of your ID card.

How do you determine which printer is the right one for your organization’s ID card presentation requirements?

The second technology is Reverse Transfer or Re-Transfer which uses a two-step process to imprint cards; first, the image is printed in reverse onto a clear receiving layer of film, then heat and pressure are applied to the film to transfer the image and the film onto the card’s surface. Although this process is more costly, it creates a more durable and clearer image with a higher print quality.

Another key design element to factor into your printer choice is single- or dual-sided card printing options. For simple text and graphics, single-sided printers which print on one side of a card are a smart choice if you only print a small volume of cards each year (generally under 500 cards). These printers are perfect for printing simple ID cards with limited information such as employee photo, name, and company logo. Dual-sided printers can print on both sides of a card in a single pass, allowing for more detail and space for more information. These printers are ideal for organizations, such as healthcare, that need room to show more detailed information or have requirements where specific information must be visible no matter which side of the card is showing.

Lastly, you’ll need to determine whether you need to select a printer that includes a lamination module. Lamination not only looks professional; it also adds durability and increases life of the card. Some printer models feature wasteless lamination technology, which results in zero lamination waste produced and requires less cost in consumables because carrier film or take-up spool are not required. Currently, wasteless lamination is offered on the Fargo® DTC5500LMX and HDP6600 models.

FARGO® ID Card Printer Capabilities are available in two different printer technologies - High-Definition Printing (HDP) using Reverse Transfer Film or Direct-to-Card (DTC) using Dye-Sublimation directly on the card.

DTC or Dye Sublimation printing is the most common technology used by desktop printers/encoders to transfer images to cards.

To find out more about HID FARGO ID Card Printers, visit our FARGO ID Card Printer Buying Guide, or ask the experts at J. O’Brien by requesting a free consultation today.

2 MIN READ

It’s official. After months of planning, testing, editing, and more testing (because that’s how we do things around here),...

5 MIN READ

Below you will find a comparison chart for J. O'Brien's line of IDP SOLID-UX printers. Use this chart to make an informed...

2 MIN READ

For years, VALCam was the go-to name in photo ID...