Direct-to-Card vs. Retransfer Card Printers: What You Need to Know

Shopping for an ID card printer? You’ll notice two main types of printing technologies: Direct-to-Card (DTC) and Retransfer. Both can produce high-quality photo ID badges, but they work differently, and choosing the wrong one for your application can result in disappointing outcomes or even damaged equipment.

Let’s break down the key differences and help you determine which type is best suited for your environment.

What Is a Direct-to-Card Printer?

Direct-to-card printers use a thermal printhead that heats dye ribbon panels and applies the ink directly onto the surface of a blank card. This is also known as dye sublimation printing. Each color panel (typically yellow, magenta, cyan, and black) is heated and transferred one layer at a time to create the final image.

Pros of Direct-to-Card Printers:

- Cost-effective hardware and supplies

- Fast print speeds

- Ideal for smooth PVC cards

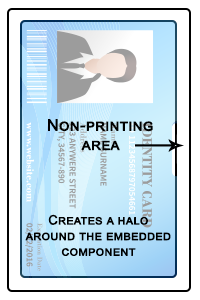

But there’s a catch — and it’s important. If you're using high-frequency cards like SEOS, or any card with an embedded chip (Crescendo or Idemia, for example), you should NOT use a direct-to-card printer. The printhead makes direct contact with the card, and any uneven surface can:

- Distort the image

- Cause ribbon breaks or smudges

- Damage the printhead over time, leading to costly repairs

And since DTC printers can't print fully edge-to-edge, you'll always have a small unprinted margin around the border of each card.

What Is a Retransfer Card Printer?

Retransfer printers (also called reverse transfer printers) use a two-step process. First, the image is printed in reverse onto a clear retransfer film. Then, that film is heated and fused onto the card's surface, permanently bonding the image to the card under a protective layer.

Pros of Retransfer Printers:

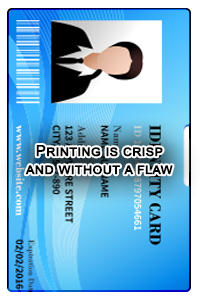

- Flawless, edge-to-edge printing

- Superior image quality and color saturation

- Safe for use with chip-embedded and uneven cards

- More durable, longer-lasting cards

Because the printhead never touches the card directly, it stays protected from dirt, dust, and the raised elements found on contact or contactless cards. This extends the life of the printer and delivers more consistent results.

Things to consider: Retransfer printers are more expensive upfront and composite cards are recommended (not standard PVC) to withstand the higher temperatures used during the bonding process. But if you're looking for print quality, durability, and flexibility, it’s worth the investment.

Which Printer Is Right for You?

Still not sure? Here's a quick comparison:

| Feature | Direct-to-Card | Retransfer |

|---|---|---|

| Card Compatibility | Smooth cards with no exposed chips | Recommended for cards with exposed chips |

| Print Quality | Good | Excellent (high resolution) |

| Edge-to-Edge Printing | No | Yes |

| Printhead Lifespan | Shorter (due to contact) | Longer (no contact with card) |

| Upfront Cost | Lower | Higher |

Need Help Choosing the Right Printer?

At J. O’Brien, we stock both direct-to-card and retransfer printers from trusted brands — and we’ll help you find the best fit for your card type, volume, and budget.

Talk to our team today or browse our card printer supplies to get started.